Canopy Footers

There are many misconceptions when it comes to aluminum canopy footings. We have seen many times where aluminum canopy footings are designed too large or are designed as if it were a steel structure. This section will lay out the different criteria to consider when designing footings for aluminum canopies and clear up any misconceptions in footing design.

There are three main factors when designing a footing for an aluminum canopy:

1) Bearing Load

2) Wind Uplift

3) Moment created due to horizontal loading on the canopy (typically wind loading) or from a cantilevered design

Bearing Load – Bearing load determines the length and width of the footing or what we call the footer “pad”. Bearing load is the weight that the aluminum canopy is putting down onto the footing (through the canopy column). The way to make sure that your footing is large enough to withstand the bearing load is simple: the weight of the canopy under full loading must be able to be held up by the ground and not sink in. An easy analogy for this is a pencil in dirt. If the force of the pencil is greater than the dirt can withstand, the pencil will sink. If the force of the pencil is less than the dirt can withstand, the pencil will not sink.

The minimum soil condition for the United States is 1500 lbs/ft^2 (this is for sandy conditions, but can be used as worst case scenario). To figure out what size the bottom dimension of the footing needs to be, take the total load going through the column and divide it by 1500. This will give you the square feet that the bottom of the footing needs to cover.

Wind Uplift – Wind uplift determines the overall size of the footing (the amount of concrete required to keep the canopy anchored to the ground). The footing size will vary depending on which part of the country it is being installed due to varying wind conditions. This is typically the hardest factor to calculate because you are determining how the wind is going to affect the canopy. ASCE 7-05 will give you the most accurate information on how wind speed affects the canopy. On average, concrete weighs 144 lbs/ft^3. The way to calculate a minimum footing size for uplift is to determine the amount of upward force (in lbs) the wind is applying to the canopy at each column, then divide that force by 144 and that will give you the minimum cubic feet of concrete to keep the canopy in place. After calculating the minimum cubic feet of concrete, remember that varying dimensions can give you the same cubic feet of concrete (ex: an 18”x18”x24” footer is roughly the same amount of concrete as a 13”x13”x40” footing). This is where you need to make sure to incorporate the minimum footer pad size from your bearing load calculations.

Moment Created due to Wind Loading – The moment acting on the canopy determines typically how deep the footing should be. The moment is basically the force created by horizontal wind wanting to tip the canopy over or from a cantilevered system wanting to tip over. The footer must be deep enough to resist this “tipping” force.

*Tips for Designing Footers*:

Here is a list of tips to keep in mind when designing footings for aluminum canopies so that they are not over-designed, or under-designed.

1) Aluminum is much lighter than steel, so the footing “pad” size for an aluminum canopy will be much smaller than that of a steel canopy.

2) A footing depth is typically based on the moment created by wind loading, but another factor is the frost line for the area the canopy is being installed. A canopy’s footing must be as deep or deeper than the frost line for that particular area.

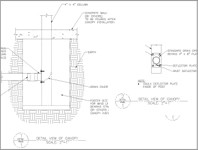

3) Footings for cantilevered canopies are deeper than standard footings due to cantilevered canopies having a much higher moment on the column.

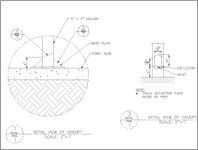

4) Aluminum reacts negatively with concrete. A bituminous coating applied to the aluminum will stop any reaction between the aluminum and concrete. A baked enamel finish qualifies as a bituminous coating. If the canopy is anodized aluminum, an acrylic coating must be applied to the column where it will contact the concrete footing to stop any reaction between the two.

5) For a typical canopy being installed in the southeast, not in a high wind region, an average footing size would be 18”x18”x20” for each column.

6) There are multiple footing styles that can be used for aluminum canopies. Below is a list (see details also)

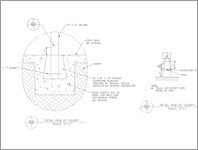

- Standard Footing using Tapered Styrofoam block-out

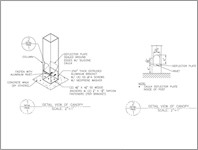

- Surface Mounting of column using welded base plates with SS epoxy anchors or SS wedge anchors

- Standard Footing with underground drainage connection

- Surface Mounting of columns using MM Surface Mount Brackets with SS wedge anchors